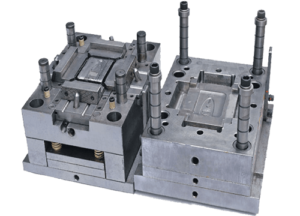

Mould Development

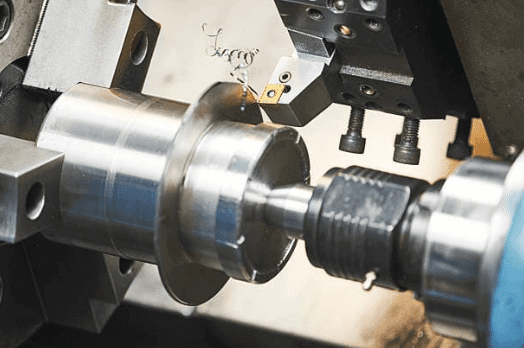

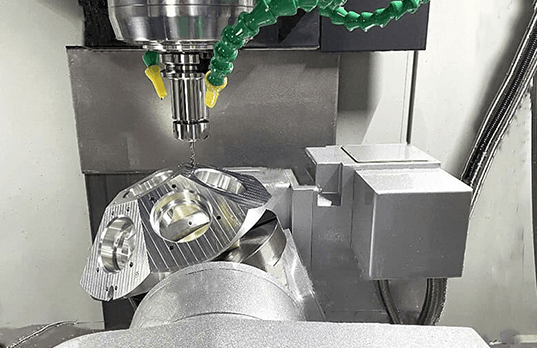

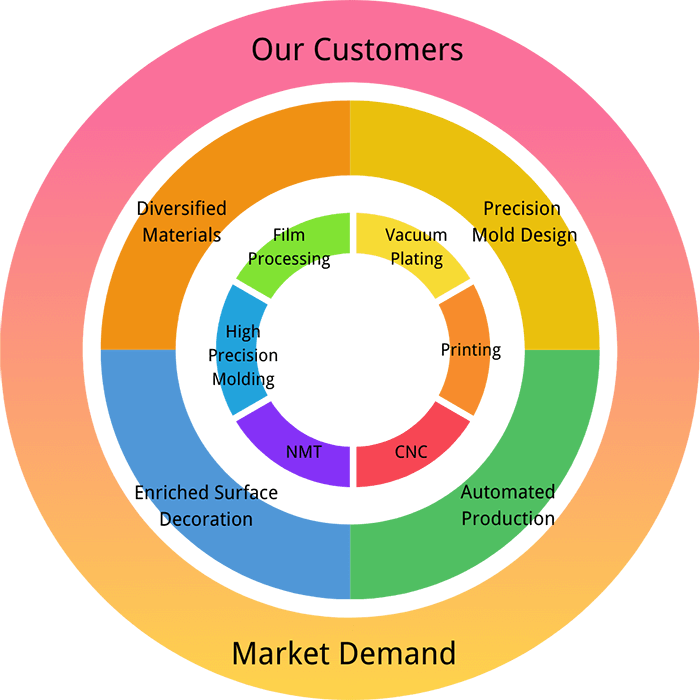

Research and development, design and production of high-precision molds are critical components of Beone Company’s industry chain. Both its design capability and development technology are of an advanced standard domestically and abroad. Beone Company has hundreds of Computer Numerical Control (CNC) machines and over a hundred sets of mold processing equipment which provide strong hardware protection and technological support for the improvement and quality of its product technology.

Major usages: A variety of injection molds, cold-punching molds, casting molds, forging molds, die-casting molds, and metal or ceramic injection molds are applied to a range of various metals, precise plastic casings, and precision components.